STEP

Evolve STEP Technology

Selective thermoplastic electrophotographic process (STEP) is our patented technology. At the core of STEP technology is the electrophotographic imaging and deposition. STEP uses the proven high volume 2D printing process to create a 3D part using heat, pressure and cooling to fuse the part material together layer by layer.

White Paper: A look into STEP Technology. Inquire Here.

TRANSFORM

First Viable Alternative to Injection Molding

The Evolve SVP platform, powered by STEP technology, frees you from your existing manufacturing constraints of making low volume production affordable, with the ability to reduce forecast estimates from 12 months to 90 days. From producing new products to part consolidation, we are transforming how the world manufactures.

What is Evolve STEP Technology and How Does it Work?

Unlike other additive technologies that have been brought to the market in past 10 years, Evolve STEP Technology has been designed and developed specifically for production manufacturing. STEP’s architecture utilizes the same three process phases – imaging, alignment and fusing – to deliver throughput and quality similar to injection molding.

One of the many benefits of the SVP platform is our closed-loop process with sensor technology; each layer of the build is precisely aligned on top of the next incoming layer and the correct amount of material is deposited. If an error is detected, a correction is made. This means a higher part quality with both repeatability and scalability.

Selective

The first word in STEP is “Selective”. Selective because STEP has the ability to lay down particles in a very precise way. Each voxel (additive description for each 3D pixel) is precisely placed in a layer with a specific material. What’s more, STEP is able to place two separate voxels of 2 different materials, side by side in the same layer (part and support).

Thermoplastic

The second word in the acronym STEP is “Thermoplastic”. This is because STEP has the ability to print parts made with true engineering ABS thermoplastics.

Electrophotographic

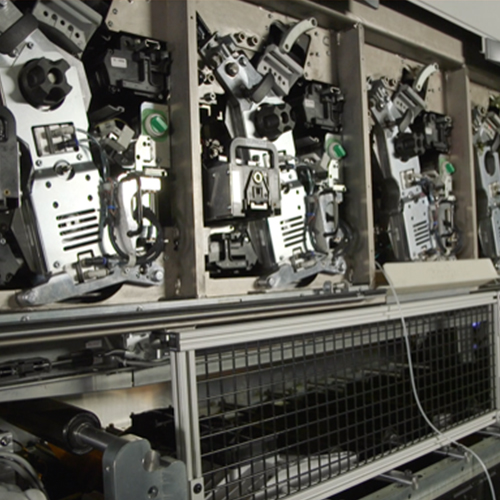

The third word is “Electrophotographic” which is a technology word for laser printer. STEP leverages the Kodak NexPress™ print engine, the highest deposition 2D print engine in the world, to image each layer. The use of electrophotography in additive is unique and it is one of the key elements that allows STEP to produce high-fidelity parts.

Process

The fourth word is “Process”. Proprietary hardware and software combine to create a controlled, repeatable manufacturing capability. Vision systems and other closed-loop controls continually monitor the print and adjust if needed in situ.

What differentiates the Evolve SVP platform?

It is the first true plastics manufacturing technology to achieve mass customization,

just-in-time production and dependable quality.