MATERIALS

Real Engineering Polymers for Real Production

Evolve STEP technology uses the same class of engineering thermoplastics trusted in traditional injection molding. This means parts produced on the SVP™ platform are not experimental or limited-use – they are true, end-use plastic components suitable for demanding mechanical, thermal, and environmental applications.

At the core of the process is Evolve’s proprietary materials formulation, which transforms standard injection-molding grade polymers into a fine particulate toner form. This toner is used both for part material and support structures, enabling precise geometry, clean separation, and high-quality surface finish.

Current Commercially Available Materials

ABS (Acrylonitrile Butadiene Styrene)

A widely used, versatile engineering thermoplastic known for:

- Strength and impact resistance

- Dimensional stability

- Ease of post-processing (machining, bonding, coating, finishing)

ABS is commonly used in consumer products, automotive interior components, housings, electronics enclosures, and industrial assemblies. Because STEP™ uses true ABS, STEP-produced ABS components can match or integrate directly with injection molded parts in both appearance and performance.

Additional materials are in development with varying roadmaps for commercial availability.

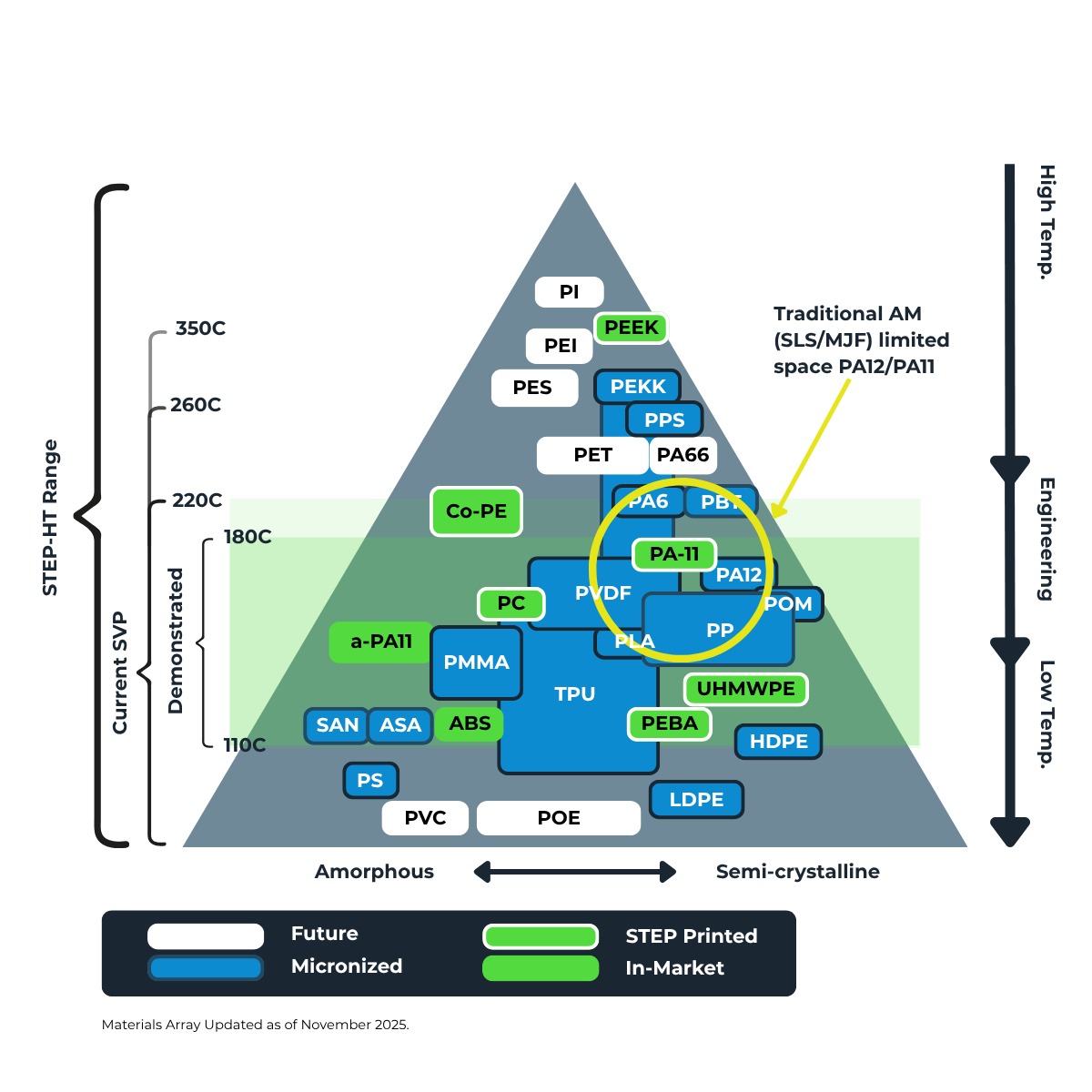

See below the range of thermoplastics STEP technology is capable of:

Material Development & Customization

Evolve actively collaborates with customers to develop and commercialize new polymers based on application requirements.

CO-PRINTING

Print multiple materials in a single process

STEP’s multi-engine system allows you to combine materials or colors in a single process. Distinct polymers, or multiple colors of the same polymer, can be printed side-by-side, blended in controlled gradients, or structured as core-shell designs. STEP preserves the mechanical performance and design of your parts while streamlining multi-material production.