REAL ABS MATERIALS

- Water-tight for leak-proofing

- Good dimensional stability in a range of environments

- Good impact resistance / toughness

- Heat-stable up to 60℃ (140F)

- Hydrolytically stable up to 70℃ (158F)

- pH stable in acidic or basic environments

REDUCED SUPPLY CHAIN LOGISTICS

- Eliminate tools that need storage / warehouses

- Reduce shipping time / cost from tool maker

- Minimize shipping time from factory to customers

Our Advantages

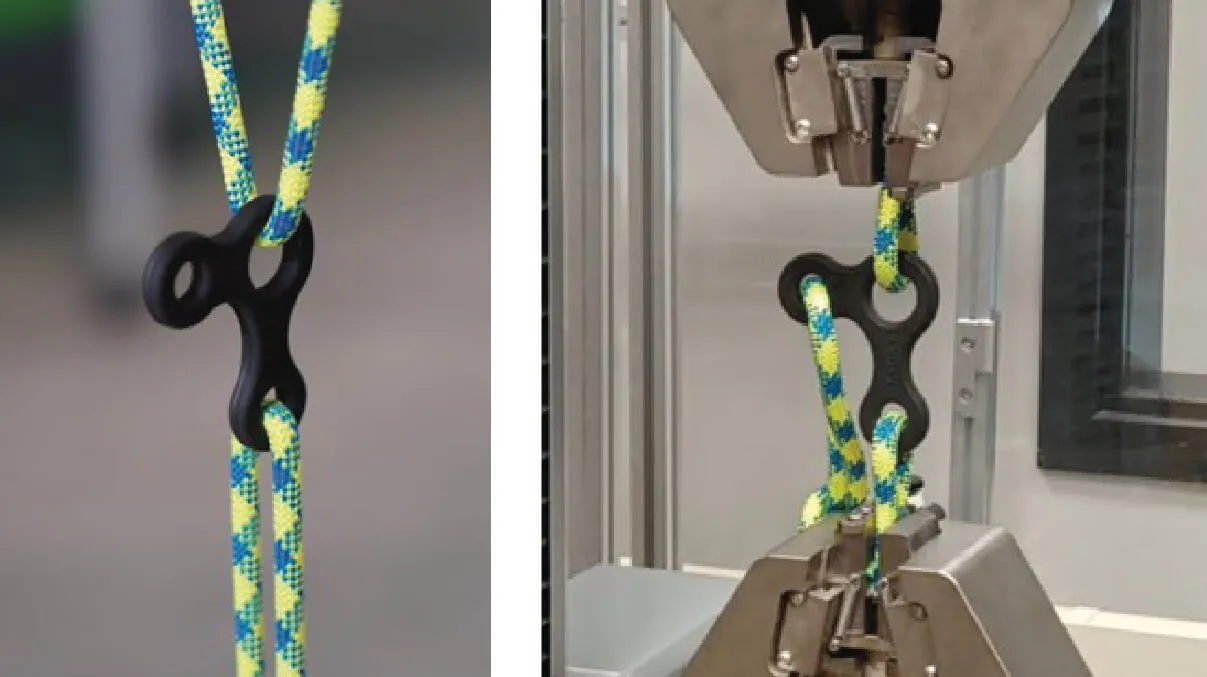

Customizable Rope Tension

Strong thick-walled part >10mm

Tensile Strength >>500lbs

Design and manufacture different geometries in same build

Sustainability: Toolless manufacturing and distributed manufacturing

Lightweight and strong

ABS is waterproof

Flexibility to match on demand production needs

Rock Climbing Hand Holds

- Able to create complex textures & shapes

- Great for strength training of extreme athletes & weekend warriors

CUSTOM / CREATIVE DESIGN POSSIBILITIES

- Highly customizable for each customer’s needs

- Eliminate production cast/mold wear

- Ability to recreate real-world rock-climbing routes with 3D scanning technology

- Avoid design limitations from casting/molding production method

FURTHER ADVANTAGES

- Durability match to current production methods

- Ability to test and make micro changes to designs in days

- Strength needs easily achieved with STEP ABS, unlike other additive technologies

Drone Blades

- Extreme Durability: production grade ABS amorphous thermoplastics

- Weight Reduction

- Speed to market, in a rapidly advancing industry

- Recyclable consumable component to larger assembly

- Ability to implement design changes for aerodynamics

- Unique or replacement parts

- Eliminate rigid molds (production file will not depreciate)

FURTHER ADVANTAGES

- Paintable or metal-platable for increased durability of customization

- Flight-ready parts are ready for flight after production