A New Way to Develop Plastic Products

Selective Thermoplastic Electrophotographic Process (STEP) produces end-use parts in amorphous thermoplastic materials – with properties and dimensional accuracy on par with injection molding. STEP printing decreases the risks during product development by delivering end-use quality parts early, with feature fidelity and repeatability suitable for the entire lifecycle of a product.

Fidelity Fit for Beyond Prototyping

- Fully fused, with zero porosity

- Smooth surfaces (3-6 μm Ra)

- Walls, pins and holes as small as 0.3mm

- Crisp text as fine as 4pt

- Injection-molding resins printed with injection-molded properties

More Innovation Than Ever Before

Free your design team from the limitations of traditional manufacturing. STEP gives product developers the freedom to integrate more advanced features, elevate design quality, and create highly desirable products without the delays and constraints of tooling.

See What’s Possible

What is STEP Technology and How Does it Work?

Selective Thermoplastic Electrophotographic Process, or STEP, is a revolutionary way to produce precision polymer parts. Based off of proven industrial 2D printing, STEP translates high throughput and incredible precision to 3D plastic parts. Mimicking the injection molding process, using heat, pressure and active cooling, STEP delivers parts produced with the agility of additive manufacturing and the fidelity of injection molding.

Ultra-Fine Powder from Engineering Polymers

Parts have very fine details – and injection-molded properties.

- STEP can use almost any injection-molding resin

- Standard resins are grown or ground into fine powders

- Powder particles can be spherical or irregular – both are ok

- Powders are classified to ensure particles are the right size

- STEP’s 22µ particles are about 50x smaller than typical 80µ powder-bed particles

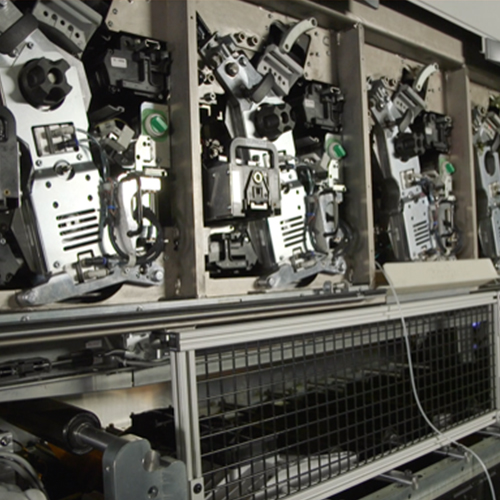

600 PPI Electrophotographic Voxelization

Parts are printed accurately, repeatably, and fast – with the ability to incorporate multiple colors or polymers.

- Part files are designed in CAD

- Files are packed and sliced

- Slice data is formatted and timed for LED writers

- The photo-sensitive imaging cylinder is exposed

- Exposed image is developed with powder from the toning station

- Each cross-section is transferred as a precise powder image

Micron-Scale Precision Registration

Part surfaces are smooth, and features are crisp and detailed.

- Imaging stations print registration patterns on the belt

- Cameras measure scale, location, and timing of the patterns

- Algorithms calculate adjustments based on belt and roller dynamics

- Industrial motion control executes precise mechanical adjustments

- Imaging data continuously refines timing and placement

- Images from multiple stations align seamlessly

Steady-State, Uniform Heating and Cooling

Parts are fully-fused, strong, tough, and undistorted — whether sparsely or densely packed.

- IR lamps heat the powder image and the top of the part uniformly

- Melted powder is pressed onto the part as the belt passes under a roller

- Active air cooling solidifies the new layer and stabilizes temperature

- Sensors monitor temperature at multiple points across the build

- Cooling airflow remains uniform across the surface

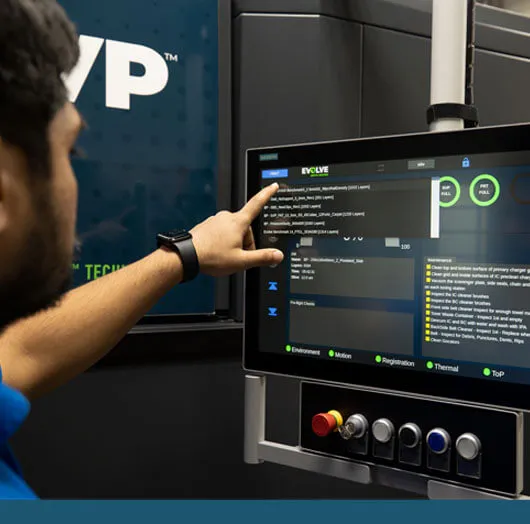

Closed-Loop Control and Monitoring of all Processes

Part dimensions and properties are repeatable, with state-of-the-art traceability and diagnostics.

- Powder electrostatic properties are continuously monitored and controlled

- Fusing pressure and layer thickness are controlled via load cells and servomotors

- Build rate is actively balanced across the print area to maintain a flat top surface within 200µ

- Top-surface scans are integrated to form a 3D model of the actual part as printed

- More than 100 process parameters are captured and logged for every job

Hands-Free Post-Processing

Part production is efficient and predictable.

- Parts are built with soluble support material, enabling nearly any geometry

- After printing, the build block is removed to cool while the machine begins the next job

- Build blocks cool for 1–2 hours before going into the wash tank

- Support material dissolves in an alkali solution — with no individual part handling

- After a water rinse, parts are ready for use; optional bead blasting or finishing steps may be applied