3D Printing with the benefits of traditional manufacturing.

It’s An Easy 3 Step Process

- Register

- Login

- Upload

How We Work With You

Upload your data for a project review with one of our experienced application experts. You will then be provided with lead times, pricing and production options.

What makes Evolve’s process so unique?

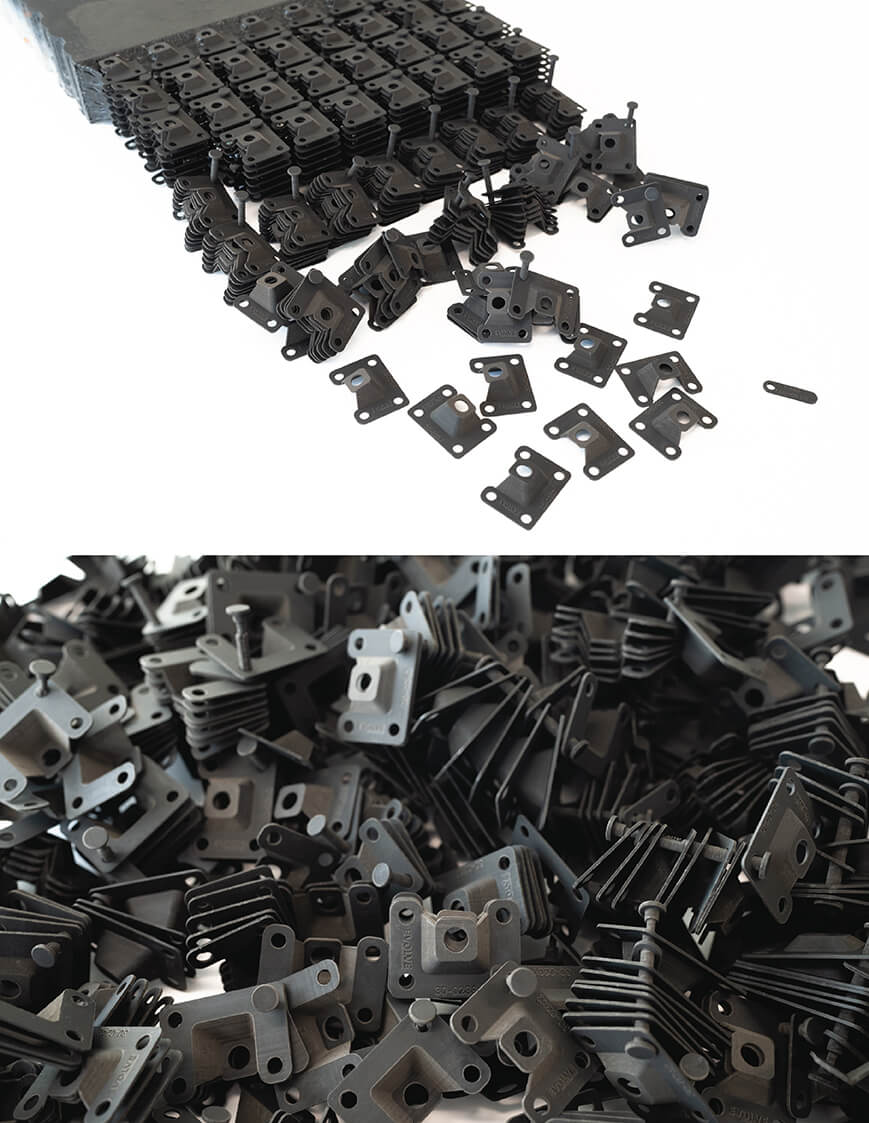

Evolve’s patent for STEP (Selective Thermoplastic Electrophotographic Process) uses proven electrophotography imaging and deposition technology producing an ultra-high-resolution part of 13-micron layers that are fully dense with low build stress.

When looking at the 3D printing polymer landscape, STEP technology did not fit into any of the traditional categorization models. ASTM and AM Power insights validated that STEP has created and owns a new category in the Additive Manufacturing industry.

Watch How STEP Technology Works

STEP’s architecture utilizes three process phases: imaging, alignment and fusing to deliver throughput and quality similar, or better, to injection molding.

What is STEP Technology?

STEP (Selective Thermoplastic Electrophotographic Process) is completely new and has been designed and developed specifically for production manufacturing. Unlike other additive technologies that have been brought to the market in past 10 years, most if not all have been derivatives of an existing technology.

STEP’s architecture utilizes three process phases, imaging, alignment and fusing, to deliver throughput and quality similar to injection molding.

One of the many benefits of the SVP (Scalable Volume Production) platform is our closed-loop process with sensor technology; each layer of the build is precisely aligned on top of the next incoming layer and the correct amount of material is deposited. If an error is detected a correction is made. This means a higher part quality with both repeatability and scalability.